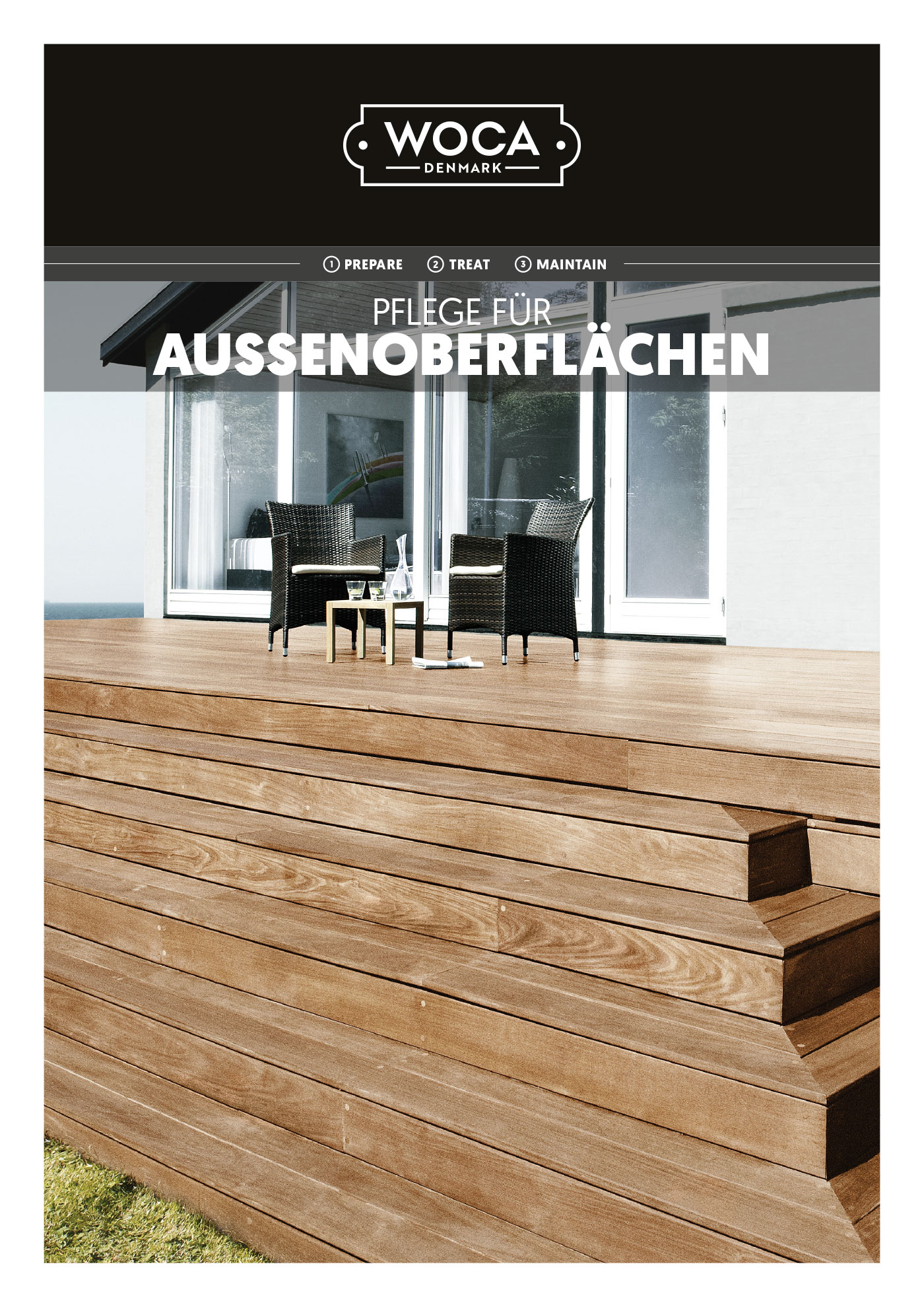

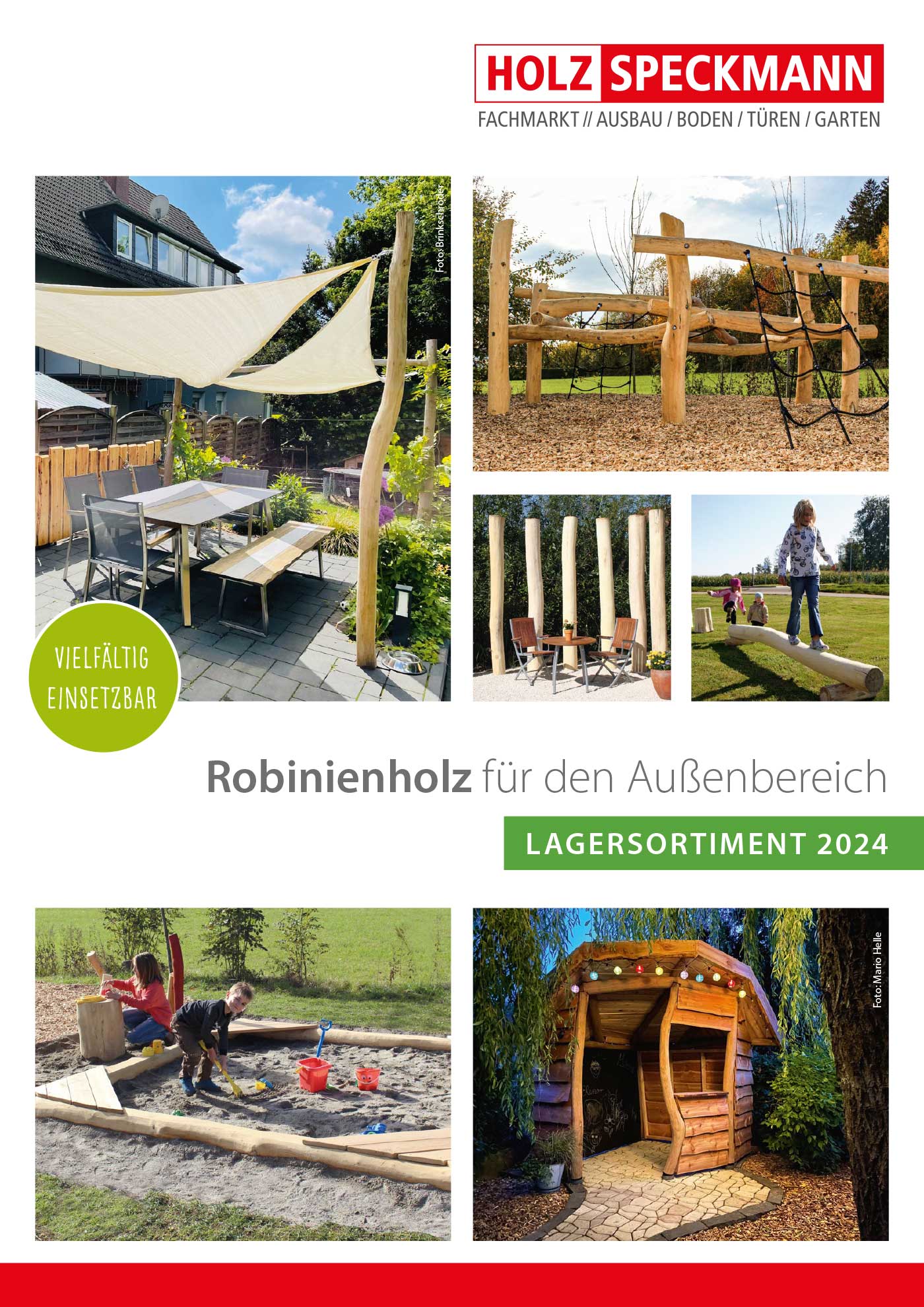

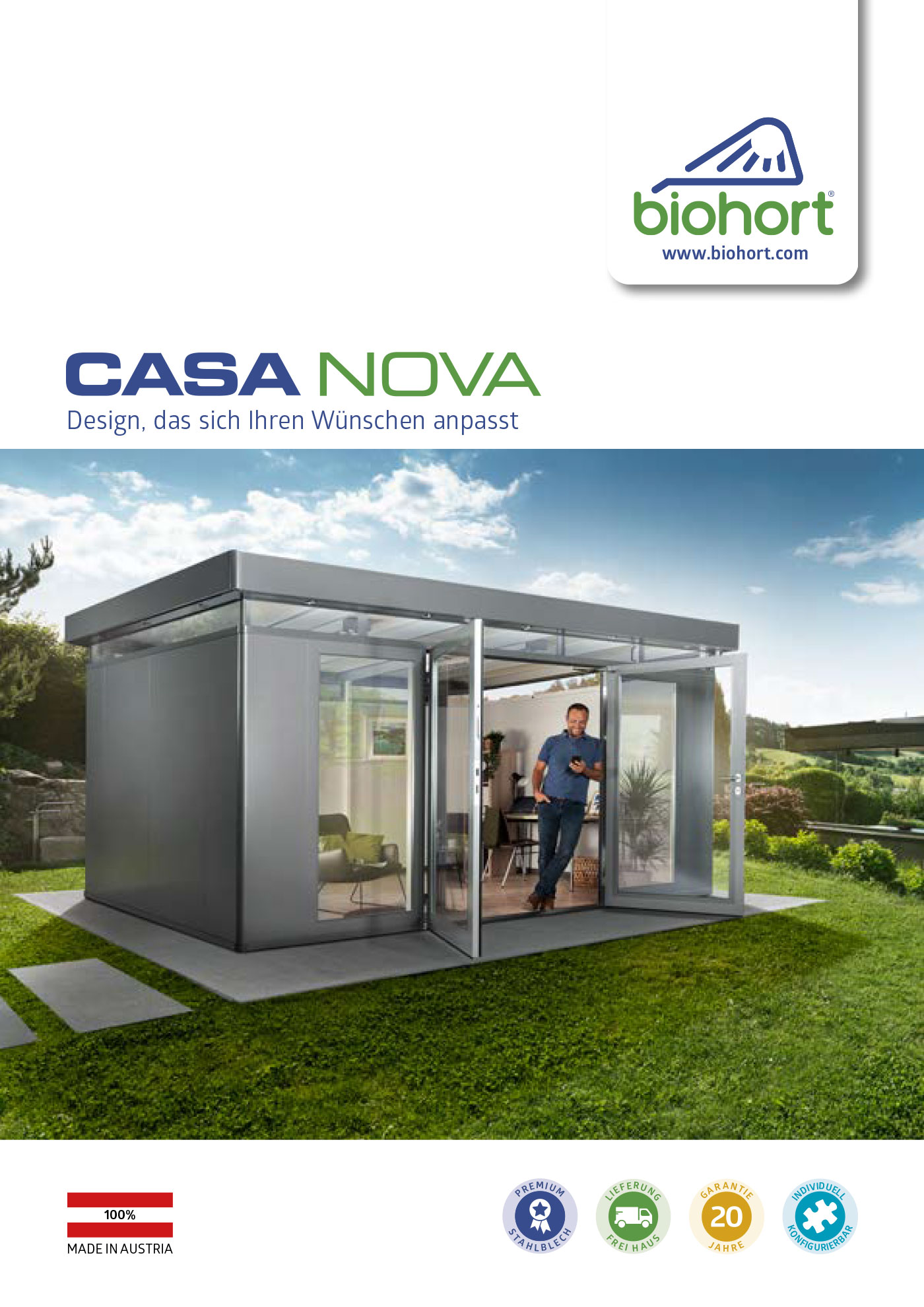

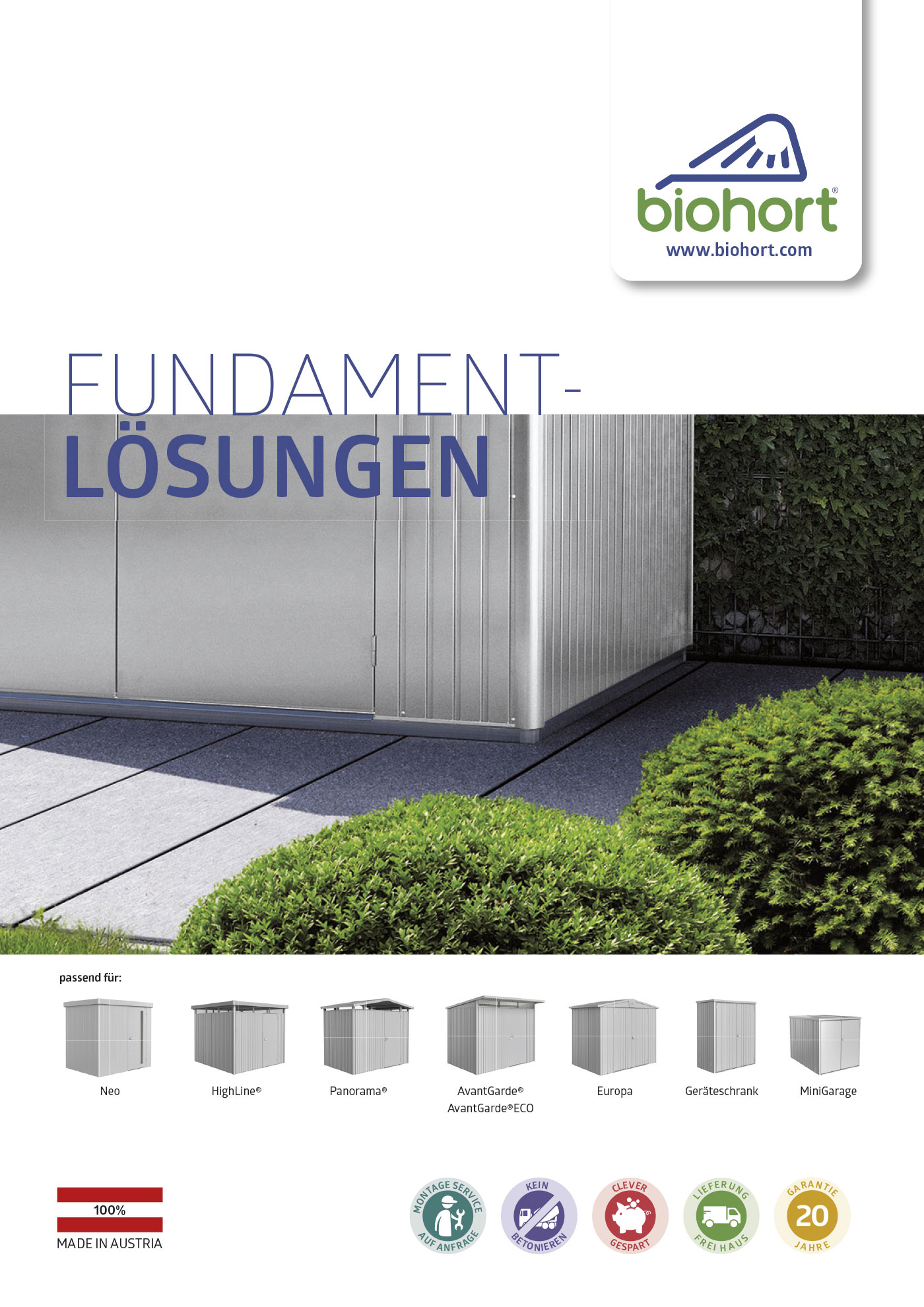

Entdecken Sie unsere Katalog-Welt

Hier erhalten Sie einen Überblick über unsere aktuellen Kataloge und Broschüren. Klicken Sie einfach auf das Bild oder Download-Symbol und Sie können sofort das PDF durchblättern oder den Katalog herunterladen.

Möchten Sie lieber in einem gedruckten Katalog blättern? – Kein Problem. Wir senden Ihnen gerne kostenfrei ein Exemplar zu. Bestellen Sie bequem über unser Anforderungsformular.

Viel Spaß beim Durchblättern! Lassen Sie sich inspirieren!